Expand your production with no additional machinery.

Air chillers increase the clarity of the blown film, boosting the output of your machinery without additional expense on acquiring more space or equipment.

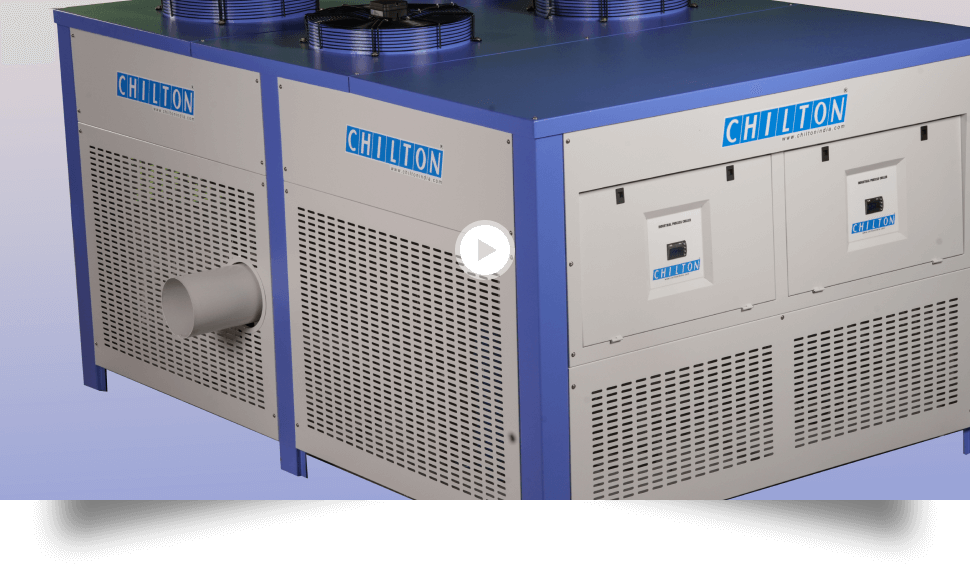

Our newly advanced Air chillers are designed exclusively for blown film extrusion application. It allows you to safely raise the cubic feet per minute (CFM) of the air without encountering any wobble problem. In addition, our process guarantees consistent bubble formation, which produces an identical film thickness and greater product integrity

The ideal mixture of dry chilled air maintains clarity and consistency of your film, thereby avoiding the attraction of water droplets and subsequent film defects.

Our chillers are plug-and-play devices, which cuts down on installation time and lets you start enjoying the benefits right away.

The ideal mixture of dry chilled air maintains clarity and consistency of your film, thereby avoiding the attraction of water droplets and subsequent film defects.

Our chillers are plug-and-play devices, which cuts down on installation time and lets you start enjoying the benefits right away.

Our Benefits

Consistency in Film Quality

Every inch of film produced meets the highest standards of quality and strength due to our precise control over air temperature and humidity.

Operational Cost Efficiency

Significant savings on your utility bills as our chillers reduce the energy required to cool air.

Production capacity

Operates between 20% to 100% production capacity.

Enhanced Structural Integrity

Dry, consistent air that enhances the physical properties of your films.

Our Features

Energy efficiency: Energy efficient & reliable inverter type variable frequency drive (VFD) compressor with hermetically sealed suction gas cooled motor.

Reliable temperature: Consistent air temperature irrespective of ambient condition which is essential for processing plastics on blown film lines.

Compact design: Our chiller doesn’t need huge land space, it covers less floor area

Control power consumption: Designed to adjust the power consumption according to the actual requirements.

Programmable logic controllers (PLC) based control with LCD display: with resistance temperature detector (RTD) temperature sensors.

Energy efficiency: Energy efficient & reliable inverter type variable frequency drive (VFD) compressor with hermetically sealed suction gas cooled motor.

Reliable temperature: Consistent air temperature irrespective of ambient condition which is essential for processing plastics on blown film lines.

Compact design: Our chiller doesn’t need huge land space, it covers less floor area

Control power consumption: Designed to adjust the power consumption according to the actual requirements.

Programmable logic controllers (PLC) based control with LCD display: with resistance temperature detector (RTD) temperature sensors.