HEAVY-DUTY CHILLERS

Durable, Energy-Efficient and Customisable According to Your Needs

Durability That You can Rely On

Chilton has recognised the importance of having a robust and reliable industry chiller. When paired with our top-end servicing, the whole process becomes streamlined.

CORE PHILOSOPHY + CORE STRENGTH

P G CHIL PRAKASH

MD & R&D

Extraordinary Features of Chilton’s Chillers

To ensure that the execution of the same is seamless, we have unique features - all limited to our brand that can make your experience with us absolutely one-of-a-kind

TURBOCHILL TECHNOLOGY

Our heat exchangers are manufactured in a way that can enhance the overall efficiency of the industry process chillers. It can withstand the harsh environment around, ensuring reliable operation and long life.

- HIGHER COOLING CAPACITY

- HIGHER POWER SAVINGS

IntelliPredict Solution

Chilton’s Process Chillers have a special IntelliPredict Solution based on AI/IOT technology – it keeps monitoring the chiller’s critical parameters and predicts breakdowns well in advance. It does so by alerting you and our team through SMS to quickly rectify the situation.

- HIGHER MAINTENNACE COST SAVINGS

- HIGHER RELIABILITY

THERMO + TECHNOLOGY

Thermo+ technology improves the chiller’s performance - it enables the machine in a way that it can withstand the hottest summer. Thus, it eliminates the common issue of chiller breakdowns in hot months.

- HIGHER RELIABILITY

- HIGHER RELIABILITY

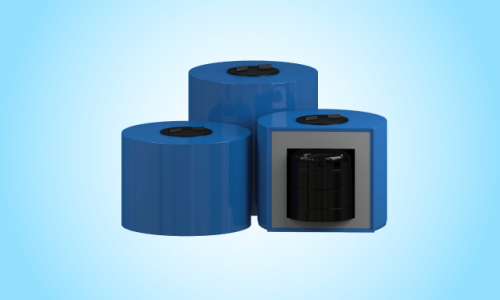

CHILLRESERVE + MODULE

Another important component of an industrial chiller is the water storage tank, yet is least efficient amongst all the other parts. Chilton’s chillers are highly insulated and have larger capacity that increases the chiller efficiency.

- HIGHER RELIABILITY

- HIGHER POWER SAVINGS

- HIGHER MAINTENANCE COST SAVINGS

ACCESSIBLE SPARE

Our chillers offer the benefit of having spare parts that are easily accessible. Naturally, the waiting time to repair/replace these parts disappears, making your operations much more efficient and fast.

- HIGHER MAINTENANCE COST SAVINGS

- HIGHER RELIABILITY

TESTIMONIALS

LOREM IPSUM

Lorem Ipsum

Application Across Different Industries

The technology which forms the foundation of our chillers is top-notch,

in a way that can SERVE 40+ DIFFERENT INDUSTRIES ALTOGETHER.

in a way that can SERVE 40+ DIFFERENT INDUSTRIES ALTOGETHER.

Food & Beverage

- Soda Manufacturing

- Cola Manufacturing

- Dairy

- Bread Manufacturing

- Extraction

- Glazing Process

- Carpet Manufacturing

- Chocolate

- Edible Oil

- Ice Cream

- Mineral Water

Plastic

-

-

-

- Blister PP

- Blown Film

- Box Strapping

- Pipe Extrusion

- Injection Moulding

- Lamination

- Non Woven

- Pet Blow

- Pre Form

-

-

Rubber

-

-

-

- Footwear

- Tyre

- Conveyor Belts

- Gloves

- Hatcheries

-

-

- Soda Manufacturing

- Cola Manufacturing

- Dairy

- Bread Manufacturing

- Extraction

- Glazing Process

- Carpet Manufacturing

- Chocolate

- Edible Oil

- Ice Cream

- Mineral Water

-

-

-

- Blister PP

- Blown Film

- Box Strapping

- Pipe Extrusion

- Injection Moulding

- Lamination

- Non Woven

- Pet Blow

- Pre Form

-

-

-

-

-

- Footwear

- Tyre

- Conveyor Belts

- Gloves

- Hatcheries

-

-

Diversified Chillers

Chilton's innovative design is sure to revolutionise the way chillers are used and provides a much needed solution to a longstanding problem

That said, we offer DIFFERENT TYPES OF INDUSTRIAL PROCESS CHILLERS,all pertaining to meet your peculiar needs.

That said, we offer DIFFERENT TYPES OF INDUSTRIAL PROCESS CHILLERS,

all pertaining to meet your peculiar needs.

all pertaining to meet your peculiar needs.

The single most important function of a chiller is to throw the heat out – into the atmosphere. Therefore, two components of industry process chillers are evaporator and condenser.

That being the foundation, industry chillers, offered by Chilton,

are bifurcated into Two categories.

BASED ON CONDENSER TECHNOLOGY

Air Cooled

Water Cooled

Brine Chillers

Glycol Chillers

BASED ON COMPRESSOR TECHNOLOGY

Reciprocating Compressor

Scroll Compressor